This is one of my most recent projects. I had been doing research on conveyor belt 3d printers and realized that all of the options were way too expensive. I realized that this just wasn’t approachable for common users. To that end I started down the path of modding an Ender 3 printer to turn it into a belt printer.

Utilizing an Ender 3 provides a couple main benefits. The first is that the mod is very cost effective. An Ender 3 can be purchased for $200 (and that’s before considering sales/discounts) and the mod ends up costing between $100-$250 depending on what parts you have on hand. The second is that this printer already supports a large number of pre-existing mods by nature of it utilizing an Ender 3. Many of the same mods you would want on your Ender 3 should be compatible here or at least require minimal changes.

Development

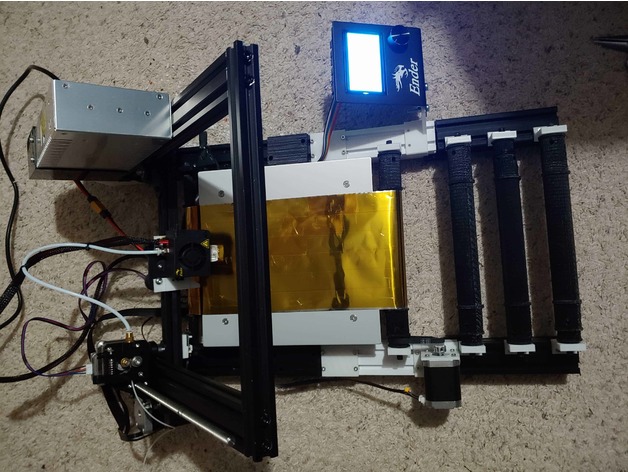

I’ve made a couple of major iterations on this project now. The first version worked, but had a few issues:

- Belt surface was warped and uneven. Part of this was just poor craftsmanship on my part when laying down Kapton tape for the belt. That said, I was really hoping for a better belt option

- Parts come off the machine elongated a bit. This was a combination of a few things. Esteps, improper part cooling, and gantry angle all contributed to this.

- The belt was curving the model print a bit. The issue was that the hot end mount wasn’t tall enough since I used the standard one on the Ender 3. This resulted in having to print material too close to the curve on the roller.

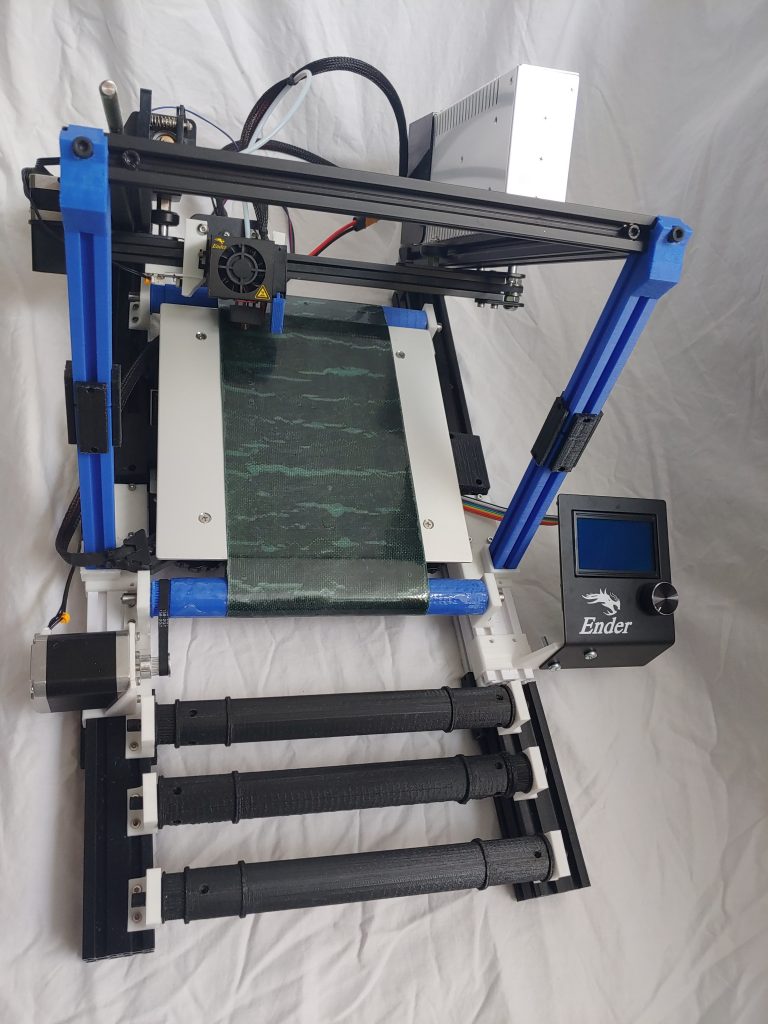

These issues led me to release the V2 designs which are now out in the wild. While not perfect, they are a huge improvement over the V1 designs and have resulted in a fully functional belt printer. A few key changes made a massive improvement. There were obviously some small firmware tweaks required, but the really consequential changes were:

- Partnering with Adam at PowerBelt for a cost effective belt for the printer. He hosts a custom sized belt for anyone who wants to make this themselves (link is in the instructions). This is a PET surface that provides better adhesion than the Kapton design from my previous iteration and the backing material grips the rollers much better.

- Improving the part cooling fan duct. This helped direct the airflow much more appropriately resulting in better material cooling.

- Designing gantry supports allowed for a sturdier printer and helped ensure an accurate 45 degree angle on the gantry.

- Vertically elongating the hot end allowed for the printer to lay material down further in on the belt. This resulted in a flat surface on the bottom of the model, removing the previous curvature issue.

Results

The final designs ended up yielding some positive prints. I printed out a few test models here: CaliCat, Benchy, and an Articulate Chameleon. These designs can all be found on Thingiverse and are all fairly tricky prints for 3d printers to handle.

CaliCat

Articulated Chameleon

The Benchy on the left is from the EnderLoop and the Benchy on the right is from a CR-6 SE for reference.

TLDR

While this is similar to the CR-30, this mod costs about 1/3-1/2 of the price (including the cost of an Ender 3), offers more mod flexibility since the core mechanics are those of the Ender 3 which already has a plethora of mods available online, and is available right now. Also, since the support extensions are 3d printed, you can cheaply and effectively add longer support than other belt printers available. The tradeoffs are that it is a bit slower than the CR-30 and requires some DIY know-how with printers.

All things considered, this is a fairly simple and cost effective means of obtaining a belt printer as an alternative to some of the available ones on the market.

I’ve got it hosted on Thingiverse and Github. There’s also an Instructable for it here.

There are a couple great YouTube resources for learning more available here and here. It’s also been featured in a Hackaday article here and in the best conveyor belt printer designs on 3dWithUs here.

It’s also won an award in the Creality Global DIY contest (article, video). And it’s been featured Instructables and was a runner up in their 2021 CNC contest.