I had been looking for a larger volume FDM printer for awhile. I know there are a few on the market, but they tend to get fairly expensive and there are some still some pretty definite caps on size (unless you are planning on a business grade printer).

Well I had waffled on a larger printer for awhile for the reasons I mentioned and just couldn’t decide on one I liked. That’s when I saw this project called Snappy listed as a RepRap project. For those who don’t know, RepRap is a collaborative initiative to make 3d printers accessible. It has resulted in some really great open source designs.

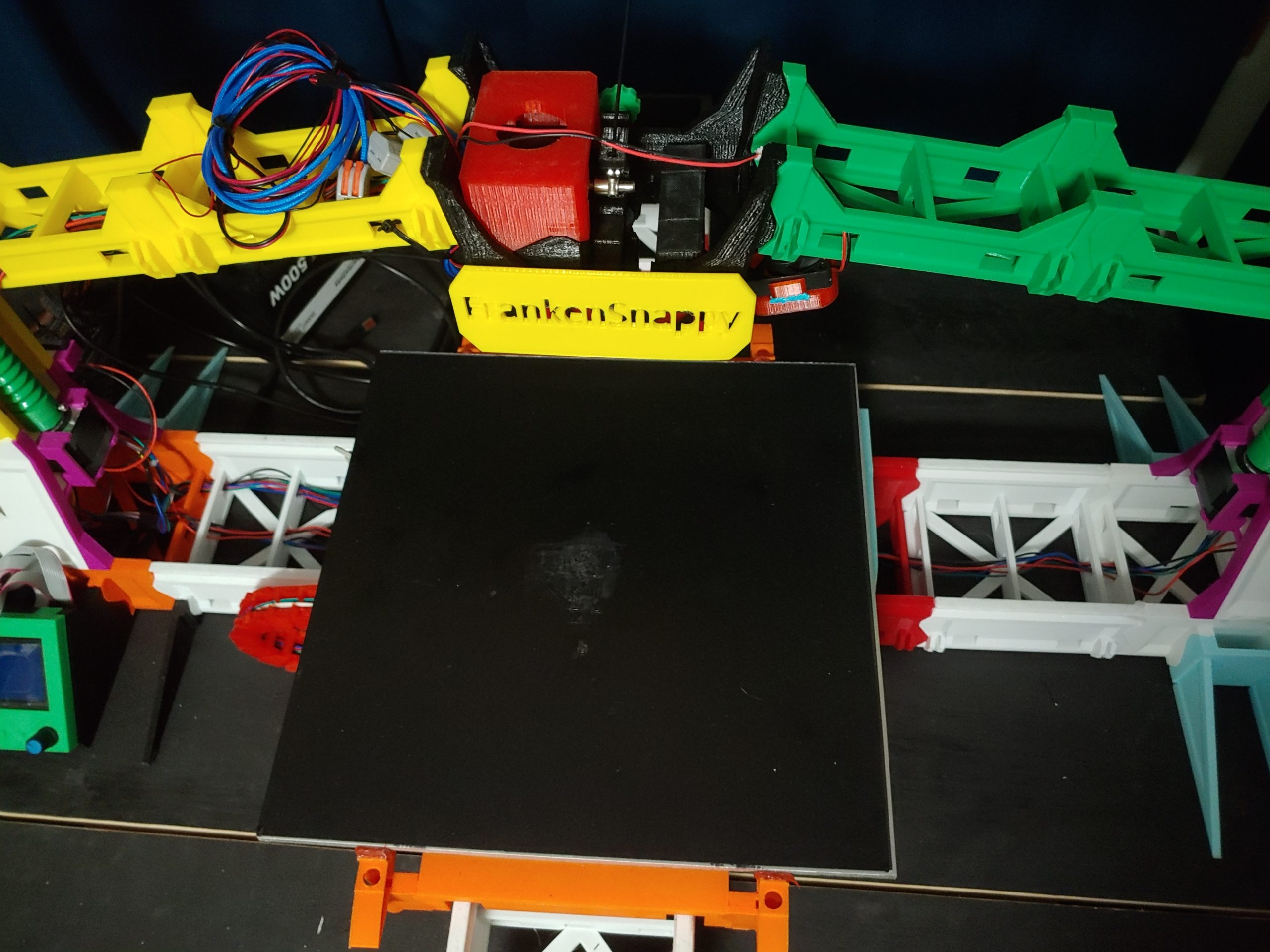

The Snappy was designed as an almost entirely 3d printed 3d printer. The great thing about this concept is that it’s relatively scalable. All the parts snap together (as the name implies), so you can increase all three dimensions by simply adding more snap together parts, at least theoretically.

What I found out part way through piecing this concept together, was that there were some design choices that meant this printer was fairly locked in at the size it was designed at. For instance, the gantry was angled so that it peaked in the middle where the hot end hangs. This means that adding more gantry pieces to make it wider would lift the hot end too high. Another problem was that a larger bed would put too much weight on the edges of the floating Y axis resulting in the printer tipping and the snap together parts starting to give.

These fixes and a few improvements led to the FrankenSnappy. It has a 1 ft. square bed and can print objects a little over a foot high. I also added an E3D hot end which is a significant improvement over the J head hot end that it was originally designed with. It also uses an aluminum backed heated bed with a magnetic PEI sheet.

There are still some small improvements that could be made, but I’m fairly happy with it. It works pretty well and can do exactly what I designed it for – print large objects. The designs for this can be found on Thingiverse.

Hi im a student, what were some of the biggest challenges you faced while developing Frankensnappy I’m actually interested on trying it out for a project.

Hi! The biggest issues are around the plastic joints supporting the movement mechanics. At that scale it’s really easy for joints to break or just disconnect.

Thanks for the reply I will keep that in mind